Warehouse Management

Warehouse Management (WMS) Systems & Software, picking, Third party logistics, Inventory control, TMS, YMS, Cross docking, Virtual Warehouse and Web based WMS for optimal stock control in the warehouse.Compact gearboxes from ABM Greiffenberger: All-clear for AGV’s

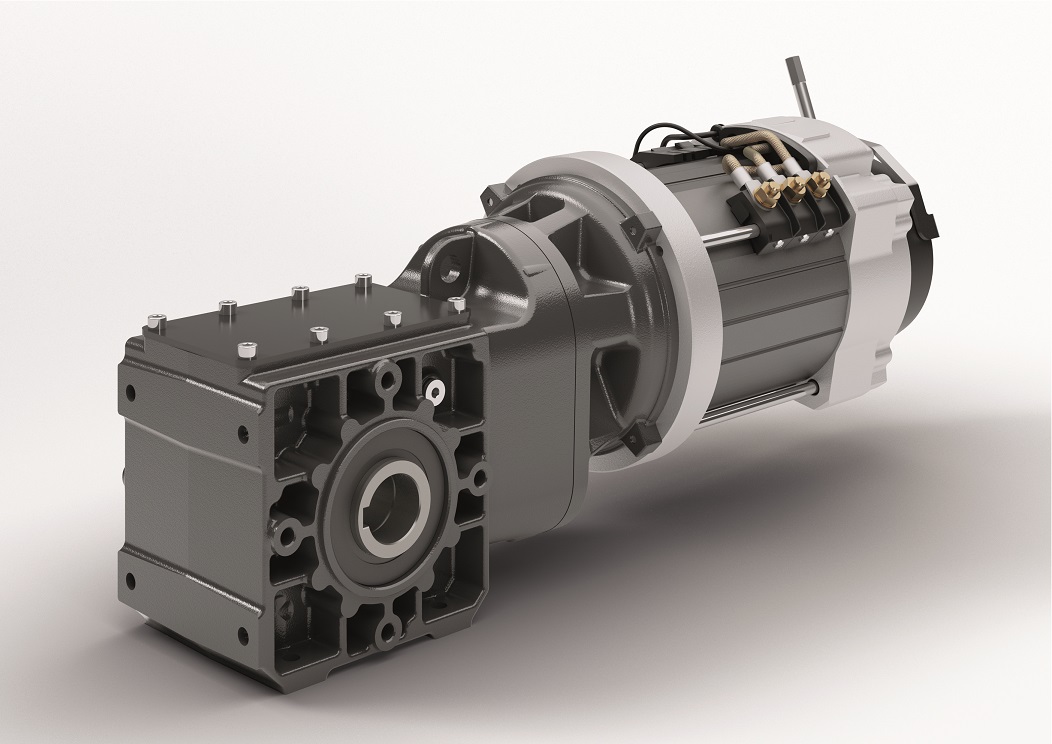

Automated guided vehicle systems can increase efficiency in production and logistics. To do so, however, they have to be powerful, safe and flexible. ABM Greiffenberger presented a series of extremely compact and space-saving gearboxes designed specifically for use in automated guided vehicles. They enable reliable and energy-efficient operation on factory floors and in warehouses.

The drive specialist from the Upper Franconian town of Marktredwitz offers efficient gearboxes for various vehicle concepts. These include towing vehicles, undercarriages, upgraded forklifts and assembly platforms. To optimally use the often tight space in an automated guided vehicle, ABM Greiffenberger developed particularly compact parallel shaft and angular gearboxes which can be easily integrated.

The two- and three-stage units are available with high reductions, low backlash and high encoder resolution. They are designed for low speeds and enable exact vehicle positioning. Depending on the drive unit design different steering versions are used, e.g., via electronic differential control of two motors for curved paths. For complex driving manoeuvres, forward and backward motion, lateral travel or rotation when stationary, one or more drive wheels can be steered electrically.

KG series bevel gears with output torques of 60 to 800 Nm are included amongst the versions that are particularly well suited to use in automated guided vehicles. FG series parallel shaft gearboxes range from 50 to 2,000 Nm. ABM Greiffenberger also has helical gearboxes in its portfolio with impressive output torques ranging from 30 to 2,080 Nm. High wheel loads of up to 25,000 N are provided by hub wheel drives (TDH series) offered in four versions with output torques from 360 to 2,000 Nm and of robust design. Through the integration of the components into the drive wheel the ABM designs excel as traction drives with particularly efficient, space-saving force transmission. Upon request bevel gear drives type TDB can be supplied with electric steering. They are available with static wheel loads of up to 16,000 N and in the different versions cover a range from 435 to 2,000 Nm. Type TDF parallel shaft gearboxes with a performance range of 435 to 1,400 Nm reach static wheel loads of up to 17,000 N.

The high wheel torques at low rotational speeds facilitate travelling on slight inclines and enable precise manoeuvring. Additionally users save costs: thanks to the high wheel loads there is no need for separate support of the wheel axle.

Sinochron Motors for Long Battery Life

Compared with forklift drives, automated guided vehicles do not require high starting torques for inclines because they are usually used on level factory floors. For autonomous operation batteries with 48 or 24 volts are frequently used. Permanent-magnet synchronous motors have proven themselves in low-voltage applications and are recommended for use here. ABM Greiffenberger offers the Sinochron series with continuous output of up to 13 kilowatts for this. This series is characterised by its compactness and high efficiency. Sinochron motors are environmentally friendly. They clearly surpass the requirements of Super Premium Efficiency class IE4. Users are hence optimally prepared for further legal regulations. The drives possess a high power density and provide for a long battery life in daily use. In addition the series is compact and can easily be integrated into transport systems.

Permanent focus on customer benefit

ABM Greiffenberger is also present in the AGV sector as a system supplier with high-level consultation and development expertise and thereby offers its customers short decision-making paths: all products are designed in-house, and even complex prototypes can be quickly produced via additive manufacturing. Modern testing technologies and a laboratory for materials analysis and motor dynos ensure consistently high quality. The parts are produced on state-of-the-art machines and machining centres; robot-controlled manufacturing cells guarantee consistent series quality. Innovative products arise out of close customer relationships and intense market monitoring. ABM Greiffenberger uses its modular and extensive portfolio to develop application-tailored, space- and cost-optimised systems.