Automation & Digital Transformation

Automatic equipment in a manufacturing, warehousing and distribution, Industrial and Autonomous research robots, Robotic process automation (RPA) and other processes or facilities.Great force in a small space

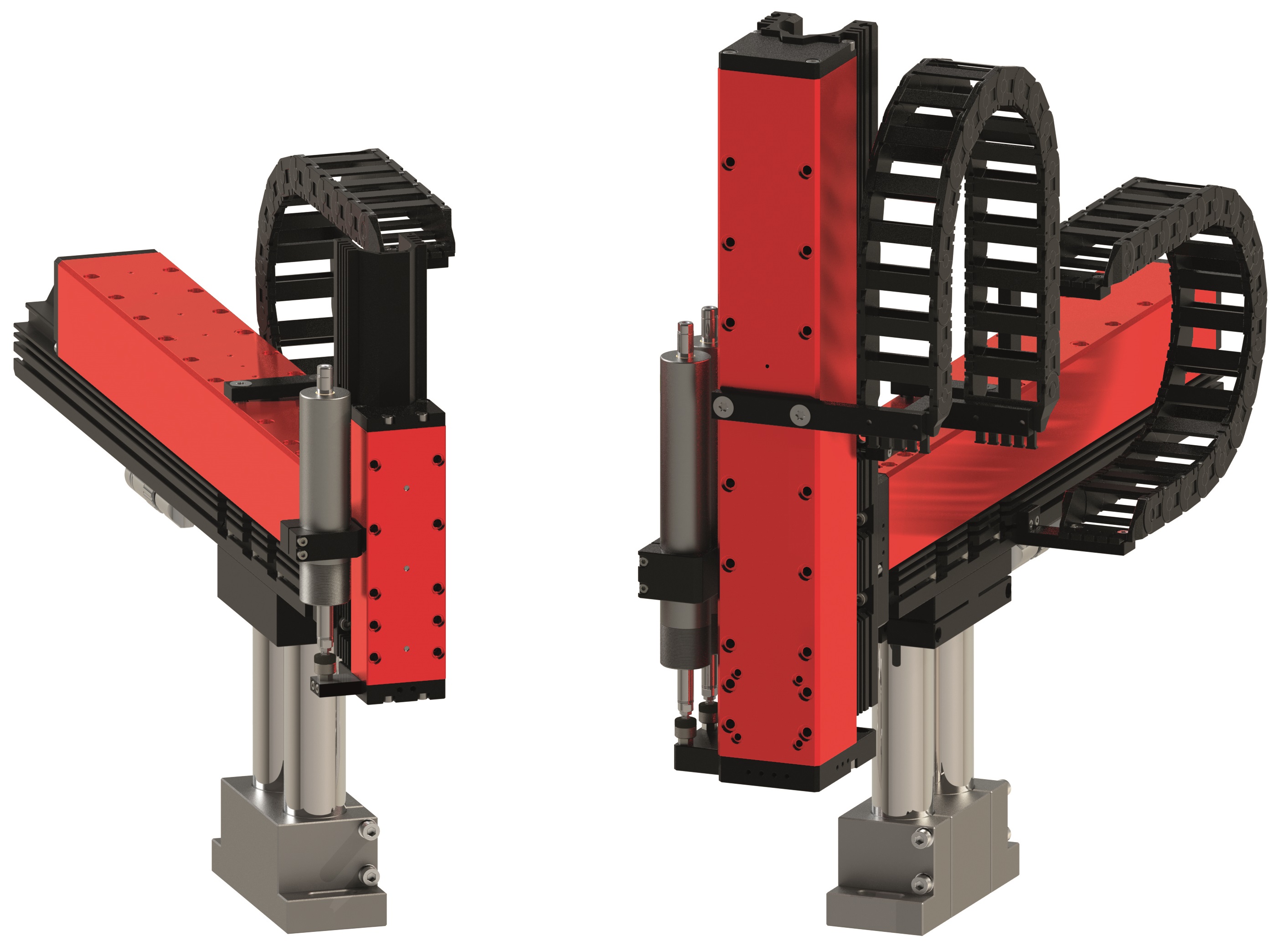

Two new handling systems for higher force ranges now complement the portfolio of YZ standard systems from handling specialist Afag. The EPS giga YZ and the EPS tera YZ are simultaneously designed for high payloads and fast, precise applications.

With the new handling systems, Afag is expanding its range to nine EPS YZ standard systems. While the EPS giga YZ can apply 255 Newton press-in forces, the slightly larger EPS tera YZ can apply 1024 Newton. This means that the user also has sufficient power available for press-fitting tasks. The new boom systems are ideal for fast movement of high payloads. The EPS giga YZ moves up to 15 kilograms and the EPS tera YZ up to 20 kilograms. The high payload does not influence the repeat accuracy of up to +/-0.02 millimeters. Standard weight compensation is available for Z-strokes of up to 500 millimeters, which ensures even shorter cycle times.

Both systems are powerful and fast: In a 1.5-second pick & place cycle, consisting of six consecutive movements and a gripping time of two times 100 milliseconds, the systems move a payload of ten kilograms by 100 millimeters on the Y axis and 100 millimeters on the Z axis, for example. The YZ stiffness is responsible for the high precision of the systems. It is made possible by an optimum slide contour of the individual axes.

Further advantages of the new handling systems are their very small width and height. This saves space. At just 180 millimeters in width, the energy chain, the optional external distance measuring system, and the weight compensation are all taken into account. With a Z-stroke of 500 millimeters including the energy chain, the EPS tera YZ is also probably the lowest handling system in its class.

Like all other handling systems from Afag, the two powerful new products contain the complete system wiring and parameterization, from the console up to the gripper jaws. They are immediately ready for use. Through the design, including cycle time guarantee and test runs before delivery, Afag guarantees the optimum functionality of the systems.