Warehouse Management

Warehouse Management (WMS) Systems & Software, picking, Third party logistics, Inventory control, TMS, YMS, Cross docking, Virtual Warehouse and Web based WMS for optimal stock control in the warehouse.Vanderlande brings item picking cobot technology to life

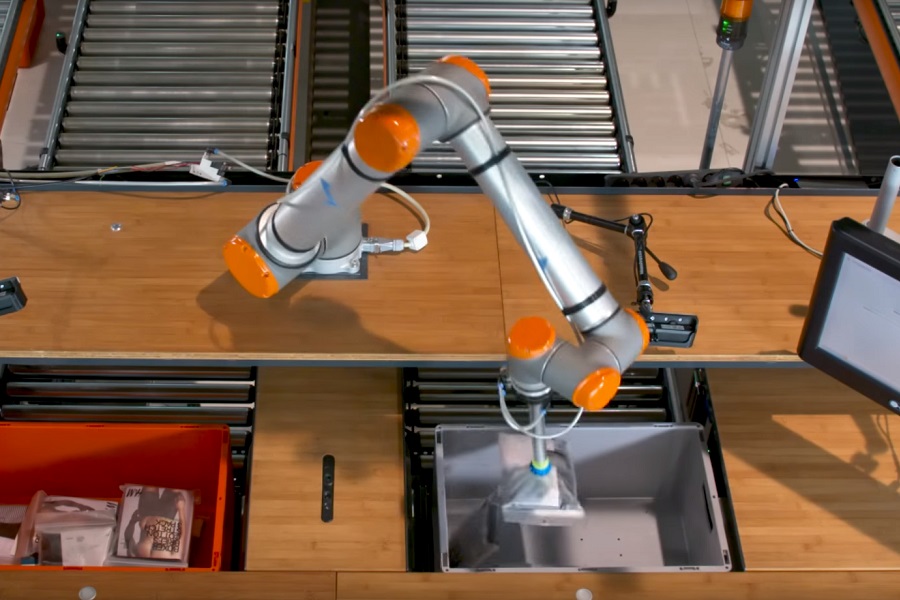

Vanderlande has developed a ‘cobot application’ (a robot physically capable of working alongside human operators) together with the leading Finnish trading company in assembly and fastening materials, Würth Oy, and their logistics software partner (Leanware Oy) in a shared pilot project. The cobot is now operational at Würth’s logistics centre in the town of Riihimäki, […]

Vanderlande has developed a ‘cobot application’ (a robot physically capable of working alongside human operators) together with the leading Finnish trading company in assembly and fastening materials, Würth Oy, and their logistics software partner (Leanware Oy) in a shared pilot project. The cobot is now operational at Würth’s logistics centre in the town of Riihimäki, just north of Helsinki.

Robotic technology has long been used in the warehousing industry for the automated movement of goods. However, the SIR (Smart Item Robotics) solution is unique, owing to its utilisation of a robot unit that is able to work harmoniously in the same area as a human operator and ability to smartly ‘pick and place’ individual items. In this way, the project addresses one of the key challenges in the market, which is the continuing lack of an available and skilled workforce.

One of SIR’s most significant strengths is its ability to handle various products without SKU teaching. In addition, intelligent stacking enables the efficient positioning of goods, while products are handled smoothly and securely.

After a lead time of less than two months, SIR has been integrated into Würth’s daily operations alongside Vanderlande’s highly flexible storage, retrieval and transportation system, ADAPTO, to seamlessly pick products for its customer orders. It can be controlled using the same Leanware system interface as other processes in the Riihimäki logistics centre and represents Vanderlande’s Smart Item Robot to be used in live operations.

“In practice, SIR is now entering school, where it will develop greatly,”says Würth’s Logistics Manager Terhi Vesala. “In the beginning, we will learn what type of products the cobot can handle, how it can better enhance the picking process on site and the most logical division of work. We are striving for total efficiency in human and cobot cooperation, so that the strengths of each can be optimised. In other words, we are experiencing what this robot is truly capable of.”

“This pilot project will give us invaluable experience in the continued development of robotic technology,” adds Terry Verkuijlen, executive vice president Warehousing and Parcel at Vanderlande. “Thanks to the logistics expertise that exists in Finland and the close partnership we enjoy with Würth, Riihimäki had the ideal conditions in which to bring SIR to life. Of course, this is an early stage in its development, so we will be proactively monitoring the situation, and working closely with Würth and Leanware to further optimise SIR’s capabilities.”