Industry Talk

Regular Industry Development Updates, Opinions and Talking Points relating to Manufacturing, the Supply Chain and Logistics.CNC Aluminum Machining for Electric Vehicle Battery Housings: Tolerances, Heat Dissipation, & Scale

EVs are fueling increased manufacturing requirements for battery enclosures. EV battery enclosures also function as load-bearing parts, dissipate heat, manage circuitry, and absorb impact. To solve these different challenges, fabrics must be made with methods that ensure accuracy, maintain design freedom, and display good thermal properties.

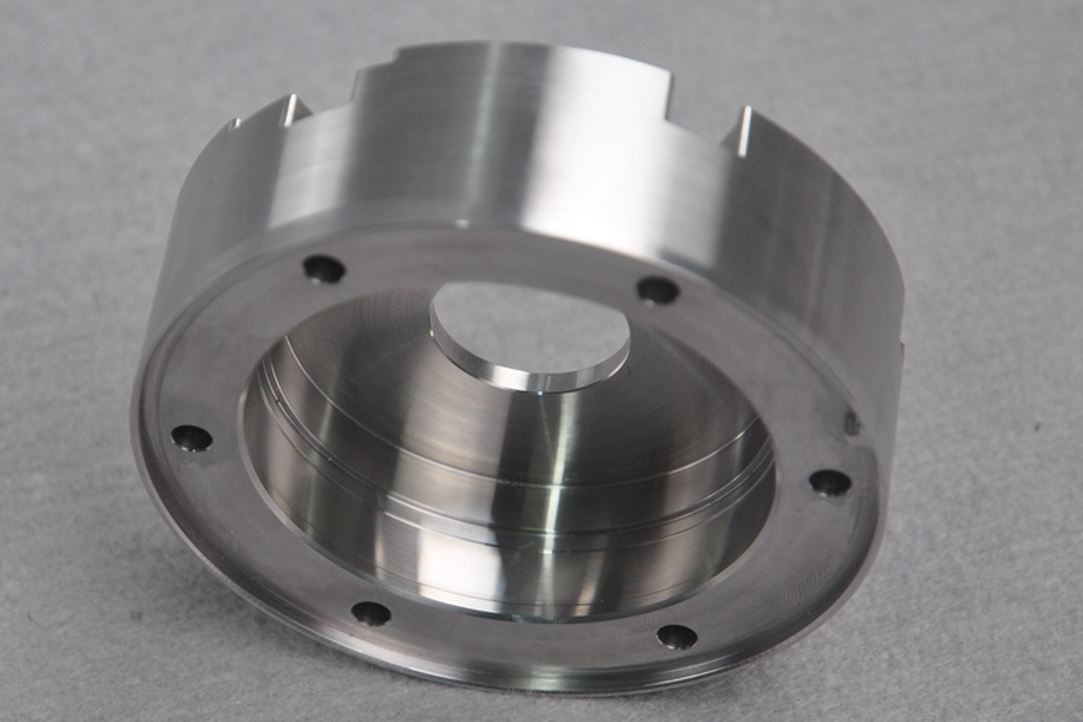

CNC aluminum machining is now considered the best manufacturing approach for EV battery housings, thanks to aluminum’s excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. From maintaining ultra-tight tolerances to ensuring efficient heat dissipation and enabling large-scale production, each aspect plays a pivotal role in battery performance, safety, and lifecycle. Advanced metal machining services offering the precision and scalability needed to bring complex battery housing designs to market quickly and reliably.

The Thermal Demands of Modern Battery Packs

EV batteries can get very hot quickly, especially when the vehicle is charged fast or driven at intense loads. The main type of batteries in EVs, known as lithium-ion cells, become heated while charging and discharging. If the heat is not ventilated, it will collect and lead to uneven heating of the cells, possible battery failure, switching off the battery, or it may even bring about dangerous events such as thermal runaway.

Since heat can be a big issue, it is very important to manage heat efficiently in the housing of EV batteries as they become more powerful. Effective thermal management helps keep the vehicle reliable and on the road for extended periods, in all conditions.

CNC aluminum machining allows engineers to achieve battery housings that comply with tight temperature standards. This design allows processors to be almost perfectly flat and enclose detailed features needed for thermal pads or heat spreaders. This allows every battery cell to experience the same level of temperature. Replacing molded plastic with machined aluminum leads to better heat transfer and overall strength. Small wastes in heat can add up and cause big differences in temperature in applications that work under high load.

As a result, many EV manufacturers rely on metal machining services to perfect the details for coolant ports, threaded fittings, and seals that contribute to various cooling methods in EVs. The overall capability of these manufacturing processes makes it possible to manage battery temperature early on in the design, ensuring safe and more efficient performance.

Why Aluminum is Ideal for Heat Dissipation

Thermal conductivity, a strong frame, and low weight make aluminum the material of choice for electric vehicle batteries. Unlike polymers, which trap heat in one spot, and unlike mild steel, which makes the vehicle heavier, aluminum helps to move excess heat away from the battery. This feature makes it possible for thermal energy to be evenly distributed. It prevents both localized heating and damage to cells while the vehicle is fast-charging or using regenerative braking.

Owing to aluminum’s low density, carmakers can achieve the required vehicle standards. Costs are kept low since injection molding parts are highly resistant to impact from moisture, changes in temperature, and vibration. CNC turning service makes it possible for engineers to build sensor ports, threaded fastener points, and inlet/outlet channels for hassle-free connection of cooling systems.

Many battery cases are made with 6061, 6082, and 7075 alloys because they are strong in heat and mechanical resistance. Because of these aluminum grades, components can be made with tight tolerances and ensure tight coupling of the fins or pads for better heat transfer with the coolant plates.

With CNC aluminum machining, every housing is cut to the right shape and size, so there are precise contact surfaces for efficient heat transmission. They can build features that cool the electronics, such as fluid channels, fins, and ribs, into the housing, avoiding the need for more items. As a result, thermal regulation is improved, it is simpler to assemble things, their reliability increases, and the development process is shorter. For electric vehicle batteries, aluminum’s strength in heat control and structure remains important as carmakers advance electric vehicles.

Scaling Production with Repeatable CNC Strategies

One major benefit of using CNC aluminum machining for electric vehicle batteries is that it allows for the proper placement of thermal features. Today, battery designs use internal heat sinks, finely cut cooling fins, and well-designed cavities for thermal pads and spreaders. They should be shaped precisely so that the material conducts heat equally and matches up next to other parts properly.

Milling these features with CNC allows them to be incorporated into the aluminum housing, so no additional fasteners are needed. It makes it easier to assemble the battery and also reduces the thermal distance between the battery cells and the cooling part of the system, increasing the entire system’s efficiency. In addition, the ability to machine extremely flat surfaces aids in heat flow by making it easier for thermal interface materials to adhere.

By creating cylindrical parts such as ports for fluids, connection points for hoses, seals, and junctions for coolant, CNC turning service increases the system’s efficiency and temperature management. When liquid or air is directed through small and tight channels in active cooling, these features are important to prevent signs of leakage and rough airflow. Operating the turning machine is especially helpful for making polished interior bores and grooves for O-rings or gaskets.

By merging CNC turning and milling in one process, engineers can build a battery housing that addresses the support and heat management needs of a single aluminum casing. Because of this approach, batteries can transfer more heat, lessen the chance of overheating, and last for a longer time. The ability to finely control thermal behavior helps EV manufacturers outperform their competitors.

Conclusion

As EV battery housings grow more complex, CNC aluminum machining delivers the precision, thermal efficiency, and scalability required for critical features like sealing surfaces and heat sinks. The CNC turning service plays a complementary role in producing high-tolerance cylindrical and threaded elements, enabling seamless integration of structural and fluid-handling components. Together, these machining strategies empower manufacturers to meet the evolving demands of electric mobility with robust, production-ready enclosures from prototype to scale.